Take a look at some of our Client case studies here.

What is Powder Coating

Powder coating is a process of applying a dry powder to a surface in order to create a durable and attractive finish. The powder is applied using an electrostatic gun, which charges the particles and causes them to adhere to the surface. The coated object is then heated in an oven to cure the powder and create a hard, smooth finish.

Some advantages of powder coating over other coating methods include:

- Durability: Powder coating is highly resistant to scratches, chips, and fading, making it ideal for outdoor applications.

- Environmentally friendly: Powder coating does not produce volatile organic compounds (VOCs) like liquid coatings do, making it a more eco-friendly option.

- Versatility: Powder coating can be applied to a wide range of materials, including metal, plastic, and wood.

- Cost-effective: While the initial cost of powder coating equipment may be higher than traditional painting equipment, powder coating can be more cost-effective in the long run due to its durability and reduced need for touch-ups and maintenance.

Some common applications for powder coating include:

- Automotive parts, such as wheels and engine components

- Outdoor furniture and equipment, such as patio furniture and playground equipment

- Architectural elements, such as window frames and fencing

- Industrial equipment, such as machinery and shelving

Overall, powder coating is a popular coating method due to its durability, versatility, and eco-friendliness.

Why Powder Coating?

Powder Coating has revolutionised the finishing industry, Powder Coating as a finishing process has grown significantly as companies are turning to powder coating as a way to produce a high quality finish that is superior, with the limitless range of colours and textures with the ability to increase production rates and the ability to cut costs.

The ease of Application

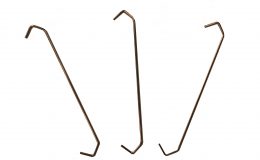

Precision powder coating is the process of spraying powder for high quality, durable and efficient finishes. Powders provide a more uniform coating because it doesn’t drip or run and the colours stay vibrant longer. In powder coating the finely ground particles of pigment and resin are electrostatically charged and sprayed onto a metal part. The coating process can be done manually or automatically with a wide variety of equipment available to small and large end users. For example by using Gema manual guns enables versatility with different extensions, flat spray, round spray and angle nozzles and being powerful ensures great powder savings and quality application with reduced operators’ fatigue with the light weight designs. This gun has innovative nozzles to optimise design and colour change. The ability to expertly manipulate powders by customising colours and textures creates many opportunities for variations. From a production point of view powder coating has the ability to cure in 20minutes which enable a piece to be ready to work almost immediately

Durability

Powder coating has been proved to be a more durable than conventional paint, due to the thermal bonding process, powder coatings are resistant to weather, chemicals, corrosion, scratching, chipping and other wear and tear. Powder coating creates a hard finish that is tough, and it has been shown to possess significant durability and resistance to abrasion, corrosion and scratching when compared to liquid coatings. Its ability to protect the toughest machinery as well as the household items, while providing an attractive finish. The end result is durable, high quality, attractive finish. The durability and longevity of powder coating can depend on the pre-treatment with cleaning and the thickness gauging afterwards. The durability is vital in common products such as refrigerators, washing machines and tumble dryers the epoxy powder coatings need to protect the appliances in any kind of situations whether by supporting the metal casing to withstand mechanical abrasion, damage from bumps and other impacts. The need to measure coating thickness is a vital part of the internal quality assurance of specifications. The QNix 8500 is a Coating Thickness gauge gives a quick and precise measurement of results for industrial painting, surface finishing and heavy duty corrosion protection. (https://www.q-nix.com/en/qnix-8500/)

Durability is reliant on the quality of the product that is produced to comply with the specifications that are required so as to give quality assurance to the end user.