Description

Technical Specifications

| Feature | Specification |

|---|---|

| Material | Anodised aluminium cup with fixed stainless steel nozzle |

| Orifice / Nozzle Diameters | Ø 3 mm, 4 mm, 5 mm, 6 mm, 8 mm |

| Calibration / Traceability | Optional factory calibration certificate on request |

| Applicable Standards | ISO 2431, DIN / EN equivalents |

| Typical Use | Viscosity measurement (flow time → kinematic viscosity) |

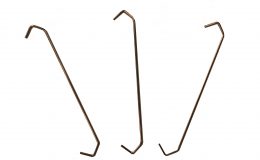

| Accessories (optional) | Cup stand / tripod, stopwatch, conversion chart (flow time → cSt), cleaning kit, calibration oils (if required) |

Art. No Ori Ø Range Material Weight DxWxH

|

CSTVF2048 |

3 mm / 0,12 “ |

7–42 cSt |

Aluminium |

337 g / 11,89 oz |

92×92 x85 mm / 3,6×3,62×3,35 “ |

|

CSTVF2049 |

4 mm / 0,16 “ |

34–135 cSt |

Aluminium |

337 g / 11,89 oz |

92x92x85 mm / 3,62×3,62×3,35 “ |

|

CSTVF2183 |

5 mm / 0,2 “ |

91–326 cSt |

Aluminium |

337 g / 11,89 oz |

92x92x85 mm/ 3,62×3,62×3,35 “ |

|

CSTVF2050 |

6 mm / 0,24 “ |

188–684 cSt |

Aluminium |

337 g / 11,89 oz |

92x92x85 mm / 3,62×3,62×3,35 “ |

|

CSTVF2051 |

8 mm/ 0,31 “ |

600–2000 cSt |

Aluminium |

337g / 11,89 oz |

92x92x85m m/ 3,62×3,62×3,35 “ |

CSTVF2061 | Tripod Stand for Viscosity Cups

CSTVF2062 | Ring Stand for Viscosity Cups

CSTVF2067 | Temperature Control Jacket for DIN & ASTM

CSTVF2068 | Temperature Control Jacket for ISO & AFNOR

CSTDI0076 | Stopwatch

CSTVF2053 | Viscosity Conversion Disc

CSTTE0027 | Precision Thermometer

CSTF2063 | Glass Plate GP20