Description

CurveX 4 Oven Temperature Logger Kit

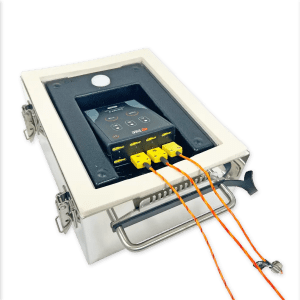

Monitor, verify, and optimise your curing process with the CurveX 4 Oven Logger Kit. Measure multiple temperature points simultaneously with the 8-channel logger, analyse data with included software, and protect your equipment with the insulation box — ensuring reliable, traceable results and improved coating performance every cycle.

⸻

How the CurveX 4 Oven Data Logger Works

The CurveX 4 data logger is used inside an insulated box and moves through the oven along with the items being cured. It can simultaneously record temperatures at multiple points on the surface of the product, giving a clear and accurate picture of the conditions inside the oven.

For added flexibility, up to 8 thermocouple probes can be connected to the logger to measure either air or surface temperatures. A variety of probe types—including magnetic, clamp, ring, and wire probes—can be used, allowing the system to adapt to different product shapes and oven setups.

This ensures that you can monitor the curing process precisely, optimise oven performance, and maintain consistent quality across every batch.

⸻

- 8-channel temperature logging: Allows simultaneous recording from up to eight thermocouple probes, enabling detailed profiling of both surface and air temperatures.

- Large memory capacity: Stores up to 1,000,000 readings, divided into 20 memory blocks (50,000 readings each), ideal for batch tracking.

- High measurement range: Supports thermocouple probes across a wide temperature span, making it suitable for a variety of oven types.

- User-friendly interface: Operated via only three buttons, with multi-coloured LEDs that provide immediate feedback on power, logging, and cure status.

- Software integration: Bundled with Ideal Finish Analysis software, which provides advanced cure-index computation, tolerance-band analysis, and professional reporting.

- Efficient data transfer & charging: Connect via USB-C to download data and charge the internal rechargeable AA battery pack. (approx. 35 hours runtime)

- Durable design: Robust aluminium and plastic housing to withstand industrial environments.

- Pre-calibrated: Factory-calibrated for immediate use, with a calibration certificate included (depending on SKU).

- Programmable paint-type settings: Pre-program your “paint type” to allow instant pass/fail assessment during logging.

- Process Optimization: Ideal for process optimisation and curing quality assurance

⸻

Technical Specifications

| SKU Kit | CSTCX4010 |

| Channels | 8 thermocouple inputs |

| Memory Capacity | 1,000,000 readings (20 × 50,000) |

| Sampling Rate | 1 second – 60 min |

| Measuring Range (probe dependent) | –100 °C to 1200 °C |

| Operating Temperature (logger) | 0 °C to 60 °C |

| Accuracy | ±1 °C (±1.8 °F) |

| Interface | USB-C for data download & charging |

| Battery Life | Approx. 35 hours |

| Housing | Aluminium / industrial plastic |

| Software | Ideal Finish Analysis |

⸻

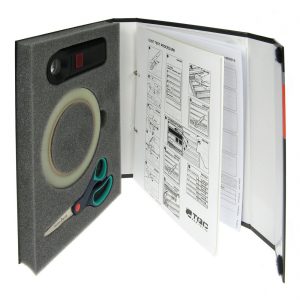

What’s included in the kit

• CurveX 4 Oven Temperature Data Logger

• Insulation Box (thermal protection barrier)

• Energy Absorber

• Silicone Seal

• Ideal Finish Analysis software (digital download)

• USB-C cable and charger

• Probe Identification Set

• Factory calibration certificate

• Protective carrying case

⚠️ Important: A data logger must always be used inside an insulation box together with the appropriate energy absorber when placed in an oven. To get the functionality from the CurveX 4 system, you will also need probes. Please find the link to the brochure below or contact us for advice on which accessories are best suited for your application.

⸻

Manufacturing and Standards

The CurveX 4 system is manufactured by Industrial Physics / TQC Sheen and supplied with a factory calibration certificate.

It supports compliance with internationally recognised coating standards such as Qualicoat, QIB and GSB, enabling reliable curing validation and traceable quality reporting.

⸻

Applications

• Powder coating curing

• Wet paint curing

• Metal finishing ovens

• Industrial batch ovens

• Conveyor ovens and tunnel ovens

• Oven performance optimisation

• Thermal process validation

• Quality control and audit documentation

⸻

Click Here for: