Description

The TQC Sheen FORD Viscosity Cup (Dip/Immersion) is a robust flow‑cup designed for measuring the viscosity of paints, coatings, lacquers and other liquid coatings in accordance with ASTM D1200. The cup is made from titanium‑anodized aluminium with a fixed stainless‑steel nozzle and handle, allowing easy dipping into product containers for quick viscosity checks. Its portable design makes it ideal for both production‑floor use and quality control in the lab.

⸻

How it Works

- Dip the cup into the fluid to be tested, ensuring it is fully immersed.

- Lift the cup vertically and start a timer as soon as the fluid begins to drain through the nozzle.

- Record the flow time — the time it takes for the fluid to empty through the orifice until flow is interrupted.

- Compare the flow time to a conversion chart or use a viscosity conversion disc to determine the kinematic viscosity (in cSt).

- For consistent and reproducible results, ensure fluid temperature and testing conditions are stable.

This straightforward “dip-and-drain” method provides a quick, reliable estimate of fluid viscosity — ideal for on-site or production-line checks, as well as coatings formulation and quality control.

⸻

Key features & benefits

- Portable dip/immersion cup — easy to use directly in containers or production vats

- Titanium‑anodized aluminium cup body with fixed stainless‑steel nozzle — durable and chemical‑resistant

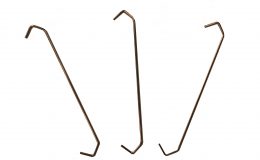

- Long loop handle — ergonomic and safe dipping in larger containers

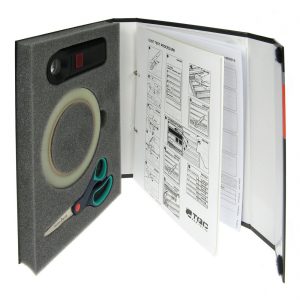

- Supplied with protective plastic storage case — safe transport and storage without damage

- Suitable for a wide range of coatings, lacquers, paints and other fluid materials

- Each cup carries a unique engraved serial number; calibration certificates available on request — good for traceability and quality assurance

⸻

Technical Specifications

| Specification | Detail |

|---|---|

| SKU | CSTVF2087 |

| Cup material | Titanium-anodized aluminium |

| Nozzle material | Stainless steel, fixed orifice (4mm) |

| Measurement standard | ASTM D1200 |

| Orifice / Cup type | Dip / Immersion Viscosity Cup |

| Typical use | Paints, coatings, lacquers, inks and similar fluids |

| Portable / handle | Long loop handle for easy dipping by hand |

| Weight | 173 grams |

| Maximum width | 63 mm |

| Cup height | 73 mm |

| Total height | 253 mm |

| Storage | Supplied in hard plastic protective case |

The TQC Viscosity Cup Immersion Ford is a range of titanium anodized aluminum or stainless steel viscosity cups with stainless steel inner cavity fixed nozzle and handle. Ideal for measuring coatings and other fluids during application or production.

⸻

What’s included

TQC Sheen FORD Viscosity Cup ASTM1200 Orifice No. 4

Hard plastic protective storage case

⸻

Accessories

CSTCL0030 | Calibration Certificate (available on request)

CSTDI0076 | Stopwatch

CSTVF2053 | Viscosity Conversion Disc

CSTTE0027 | Precision Thermometer

CSTDI0076 | Stopwatch

CSTVF2053 | Viscosity Conversion Disc

CSTTE0027 | Precision Thermometer

⸻

Manufacturing and Standards

The TQC Sheen TQC Sheen FORD Viscosity Cup are manufactured in the Netherlands (Europe) by Industrial Physics, a leading provider of coating test equipment. Each cup is engraved with an unique serial number for traceability. It meets the ASTM D1200 Standard, ensuring reliable viscosity measurements. The ASTM D1200 test method will determine the viscosity of Newtonian or near-Newtonian paints, varnishes, lacquers, and related liquid materials with a Ford-type efflux viscosity cup. If you want to work with non-Newtonian material that’s shear-thinning or thixotropic, then ASTM D2196 is a better fit.

Click here for: